As the top priority in the development of modern construction industry, prefabricated buildings have always been the key to the upgrading and transformation of China's construction industry to green energy saving, low-carbon environmental protection direction, and have played a key role in many fields such as urban and rural construction and rural revitalization in recent years.

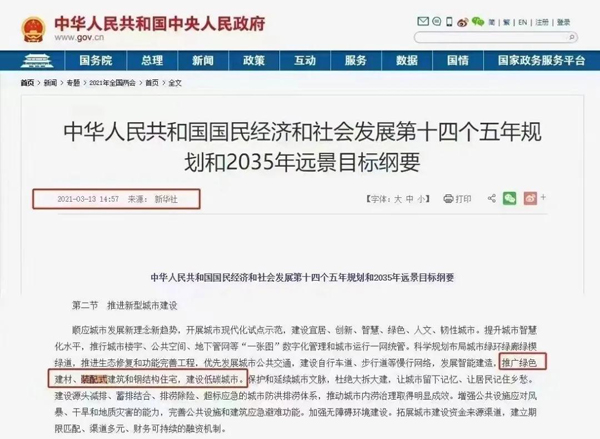

From the "13th Five-Year Plan" proposed "vigorously develop prefabricated buildings, and strive to use 10 years to make prefabricated buildings account for 30% of new buildings" to the "14th Five-Year Plan" clearly stated that "promote green building materials, prefabricated buildings and steel structure housing, and build low-carbon cities." The housing and construction departments in various regions of the country have intensively introduced a number of supporting policies and construction goals to vigorously promote the development of prefabricated buildings.

In March 2021, the Ministry of Housing and Urban-Rural Development Standard Quota Department issued in the "Ministry of Housing and Urban-Rural Development Standard Quota Department on the Development of National prefabricated buildings in 2020" pointed out that in 2020, 31 provinces, autonomous regions, municipalities directly under the Central Government and Xinjiang Production and Construction Corps of new construction of prefabricated buildings totaled 630 million square meters, an increase of 50% over 2019. The proportion of new construction area is about 20.5%. Under the active guidance of the government, China's prefabricated buildings are ushering in a period of rapid development.

Today, Xiaobian has compiled 10 important knowledge points in the field of assembly, using plain words to help you easily understand assembly architecture and help you better grasp the opportunities of The Times.

1. What is prefabricated construction?

Prefabricated building refers to a building where the main parts of the building's structural system, peripheral protection system, equipment and pipeline system, and internal system are integrated with prefabricated parts and meet the relevant evaluation standards. Prefabricated buildings are mainly divided into prefabricated concrete buildings, prefabricated steel structure buildings and prefabricated wood structure buildings, which are mainly characterized by standardized design, factory production, assembly construction, integrated decoration, information management and intelligent application.

2. What is the relationship between prefabricated building and construction industry modernization?

The modernization of the construction industry refers to the adoption of modern industrial production methods instead of on-site casting operation methods to build building products, through standardized design, factory production, assembly construction, integrated decoration, information management, improve project quality, promote green construction, achieve energy saving and emission reduction, improve the living environment, is the inevitable trend of the transformation and upgrading of the construction industry.

The modernization of construction industry has different connotation and extension in different development stages. At this stage, the connotation of the modernization of the construction industry is to take the development of prefabricated buildings as the starting point, industrialization and information as the driving force, and promote the transformation and upgrading of the construction industry and sustainable and healthy development through the reform of construction methods and collaborative innovation of the industrial chain. To achieve the goal of reducing on-site operations, reducing resource and energy consumption, reducing environmental pollution, improving construction quality, improving labor production efficiency, and improving comprehensive benefits (i.e., "three reductions and three improvements").

3. What is the relationship between prefabricated buildings and green buildings?

Prefabricated construction refers to the construction of prefabricated parts assembled on the site, focusing on the change of construction methods. Green building refers to the building that saves resources (energy saving, land saving, water saving, material saving), protects the environment, reduces pollution, provides people with healthy and suitable space for use, and harmoniously co-exists with nature during the whole life period, focusing on the result. Prefabricated building is an effective way to achieve green building.

4. What is prefabricated building structural system?

The prefabricated building consists of four major systems: structural system, peripheral protection system, equipment and pipeline system, and internal installation system. Prefabricated building structural system refers to the whole of structural components assembled by reliable connection to bear or transfer loads. Structural system is the most important part of building system, so in the design of prefabricated structure, we should pay attention to the concept design and the establishment of structural analysis model, as well as the connection design of prefabricated components.

5. What is the prefabricated building perimeter system?

The prefabricated building exterior protection system is composed of building exterior wall, roof, exterior doors and Windows and other parts, and is used to separate the indoor and outdoor environment of the building as a whole. The outer protection system is an important part of the prefabricated building, in the design, the outer protection system in addition to meet the wind resistance, seismic, impact resistance and fire safety performance and structural load requirements, but also meet the thermal insulation, thermal insulation, sound insulation, waterproof, moisture-proof and other functional indicators and durability requirements.

6. What is a prefabricated building interior system

The interior installation system of the prefabricated building is composed of the floor, wall, light partition wall, suspended ceiling, internal doors and Windows, kitchen and toilet, etc., to meet the overall requirements of building space use. The internal system can be divided into eight major systems: integrated bathroom system, integrated kitchen system, integrated floor system, integrated wall system, integrated ceiling system, door and window system, water supply system and drainage system. "Separation of pipeline and structure, elimination of operations, getting rid of dependence on traditional handicrafts, energy saving and environmental protection characteristics are more prominent, and later maintenance and renovation are more convenient" is the core value of the assembled interior system.

7. What is building system integration?

Based on the assembly construction method, it is a process of overall planning, design, production and construction to realize the integration of building structure system, peripheral protection system, equipment and pipeline system and internal installation system. Prefabricated buildings emphasize the integration between these four systems, as well as the integration process within each system.

8. What is the building module?

In architectural design, in order to achieve industrial large-scale production of buildings, building components and components of different materials, different forms and different manufacturing methods have certain commonality and interchangeability, and unified selection and coordination of value-added units of architectural scale. Building module refers to the selected size unit, as a value-added unit in scale coordination, but also the basis for the scale coordination of architectural design, building construction, building materials and products, building equipment, building components and other departments, the purpose of which is to make the installation of components consistent, and interchangeable.

9. What is the prefabricated building dry work method?

Dry construction method refers to the construction method using dry work construction. The traditional construction site in China has many problems such as wet operation, poor construction accuracy, complicated process, long construction period, relying on the level of site workers and difficult to guarantee construction quality, etc. Dry construction can achieve high precision and high quality. Therefore, dry construction method is the core content of prefabricated construction.

10. What are the advantages of prefabricated buildings over traditional construction methods?

Compared with the traditional construction method, the prefabricated construction has five advantages, such as resource saving, excellent quality, diverse styles, accelerated construction period and controllable cost. If the dust, noise and sewage of the site operation are greatly reduced, 80% water saving, 70% energy saving, material saving 20%, time saving 70%, land saving 20%, workers are also greatly reduced, and the construction process can well achieve "five sections and one environmental protection", in line with the national energy conservation and emission reduction and green development goals. The standardized process of prefabricated construction replaces extensive management, mechanized operation replaces manual operation, factory production replaces on-site operation, ground operation replaces high-altitude production, and industrial workers replace straggly soldiers, which effectively guarantees the construction quality and safety and construction efficiency.

| 上一条:Market status and market characteristics analysis of China's prefabricated construction industry in 2021 | 下一条:Precautions for the use of saber saw |

HOME

HOME

Products

Products

TEL

TEL